What types of evaporative coolers are there?

Evaporative coolers range in size from small portable models to large ducted models for residential and commercial/industrial applications. Go to What is Evaporative Cooling to learn more about evaporative cooling and its benefits.

Can evaporative coolers be used in different climates?

Evaporative cooling is best suited for climates where the air is hot, and humidity is low. They may be a cost-effective option in some higher humidity areas. Use for spot cooling, garages, workshops, garden centers, auto shops, dog kennels, outdoor tents, horse stables, exercise areas, industrial plants, commercial kitchens, farming (i.e. poultry, hog, and dairy buildings), laundries, dry cleaners, and greenhouses.

Which is better – an evaporative cooler or an air conditioner?

That all depends on you. Evaporative coolers provide continuous fresh, cool air and are energy efficient to operate. Use an evaporative cooler for whole house cooling or combine an evaporative cooler with an air conditioning system.

How do I size a cooler?

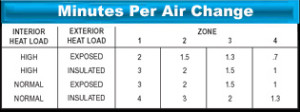

Evaporative coolers are sized based on the amount of airflow needed or CFM (cubic feet per minute). There are two ways to size a cooler. See an example here.

One, you can calculate the cubic feet of an area by multiplying the length by the width by the height (L x W x H). Once you’ve determined cubic feet, multiply that number by an evaporative cooling climate factor for your area. Referring to a specification chart for a particular type of cooler, you can determine which model meets your needs. See Sizing a Cooler.

Two, determine the total square footage of your home referring to a square foot sizing guide. Please note, however, square foot ranges shown in any guide are based on ceiling heights of 8′ and other assumptions (i.e. desired room temperature and heat loads, etc.). Square footage sizing guides are approximations only. Since conditions vary from house to house, contact a salesperson or contractor for additional information.

How do evaporative coolers rid my house of indoor pollutants?

Evaporative cooling constantly exchanges the air instead of re-circulating it so stale, polluted inside air is replaced with fresh, filtered outside air that has been cooled.

Do evaporative coolers save energy?

An evaporative cooler uses 70% less power than air conditioning. The annualized energy savings make evaporative cooling a cost effective alternative to air conditioning.

How often should my cooler be serviced?

Regular maintenance will extend the life of your cooler and help avoid unnecessary problems associated with parts replacement. We recommend servicing your cooler three times throughout the year – at start-up, mid-season, and shutdown. Refer to your Owners Manual for the recommended maintenance schedule for your cooler. Check out this page for more information on how to maintain your unit.

Is it okay if I use soft water with my evaporative cooler?

No.

Soft water may cause corrosion decreasing the effective life of your cooler.

I see scratches on my cooler. How can I get rid of them?

Should a scratch or any bare metal appear on your cooler, sand the area with steel wool to prepare the finish. Paint with standard spray paint or touch up paint available from a dealer.

What is a BLEED OFF KIT ?

The bleed-off helps your cooler function at its optimum. By continuously eliminating a small quantity of water from re-circulation, it reduces scale build-up and dilutes mineral concentrations. Consult your Owners Manual to determine the correct flow rate for your model.

You can also use a POWER-CLEAN® kit. This can reduce the amount of water used.

Is it important for my evaporative cooler to be level to operate properly?

Yes. When an evaporative cooler is mounted level, then the water within the pan is set at the appropriate level for the pump to operate efficiently. If the pump doesn’t have enough water to circulate, it will prevent the right amount of water from reaching the pads and will possibly create dry streaks. This would allow warm air to enter the evaporative cooler.

When I turn the fan on, no air is discharged. Why?

It’s possible the electrical power to the unit has been disconnected. Check fuses and/or circuit breaker. On portable or window coolers, make sure the cord is plugged in.

My evaporative cooler produces an unpleasant odor. What can I do?

Drain, flush and clean the reservoir. Make sure the cooler has a bleed-off. Clean or replace pads, if needed.

The cooler doesn’t seem to be cooling.

You could have inadequate exhaust. For every 1,000 CFM of air delivery, 2 square feet of unrestricted air relief is needed. Check the water distribution system to ensure there is adequate water reaching the pads. Clean and/or replace the distribution system if needed. Also, check the pads to make sure they aren’t clogged. If they are, clean and/or replace as needed.

I’ve heard about relief air. What is it?

As an evaporative cooler draws fresh outside air through the cooler into the home, hot stale inside air is exhausted out of the home. This is referred to as relief air. Generally speaking, a good relief design exhausts slightly more air out of the home than your cooler supplies.

How many windows and doors must I leave open?

It’s all based on the unrestricted exhaust air openings your home requires. For every 1,000 CFM of air delivery, allow 2 square feet of unrestricted air relief through windows or doors.

Are there other ways to exhaust air in my home?

Yes!

VENTMATIC™ vents can be installed to exhaust air through your attic and out the roof vents. Remember to provide 2 square feet of relief for every 1,000 CFM of air delivery.

What is VENTMATIC™ ?

VENTMATIC™ is a brand name of ceiling vents that allows for air exhaust through an attic. This also cools down the attic temperature. When the cooler comes on, the air pressure automatically opens the barometric dampers. When the cooler turns off, the damper automatically closes.

How many VENTMATIC™ vents should I install?

At a minimum, install VENTMATIC™ vents in every major room. For maximum cooling comfort, install one VENTMATIC™ vent for every 500 CFM of air delivery.

How can I direct cooled air into various rooms?

Direct the air exhaust by changing the direction of the vents or opening windows or doors in different rooms. Remember to allow a total unrestricted area of relief of 2 square feet for every 1,000 CFMs.

Are thermostats available for evaporative coolers?

Yes!

Thermostats are available for whole house coolers.

What can I expect the discharge air temperature to be from my evaporative cooler?

That depends on a number of factors. The discharge temperature is determined by the temperature and relative humidity of the incoming air. To determine the temperature of the air leaving the cooler, you will need to know the outside dry bulb temperature, the current outside wet bulb temperature, and the evaporative efficiency of the evaporative cooler (typically provided in product brochures under Performance Data). This should provide a guide to approximate discharge air temperatures.

What should I do if I won’t be using my evaporative cooler for a period of time?

Always drain the water from the cooler and start with fresh water if it has not been in operation for a week. If you are shutting down the cooler for an extended amount of time or the season, drain the water and clean the cooler. Cover cooler after cleaning.

What is a portable evaporative cooler?

A portable evaporative cooler requires no installation or wiring and can be used anywhere spot cooling is needed. Suited for residential and commercial applications, use portable coolers to cool rooms, offices, garages, workshops, garden centers, auto shops, dog kennels, outdoor tents, horse stables, exercise areas, industrial plants, commercial kitchens, farming (i.e. poultry, hog, and dairy buildings), laundries, dry cleaners, and greenhouses.

Where should I place a portable cooler?

The most important thing is to place a portable evaporative cooler where there is plenty of fresh air. The best position is adjacent to an open window or external door with additional openings on the opposite side of the room for relief air. This placement will provide the most cooling comfort.

How often should I clean a portable evaporative cooler?

Empty and replace the water reservoir at least once a week with fresh, clean water to reduce scale or mineral deposits from building up on the pad. At a minimum, clean your cooler (water system and filters) at least once during the season or more periodically depending on usage. This will help maintain the high performance of your cooler. Refer to your Owners Manual for required maintenance and scheduling.